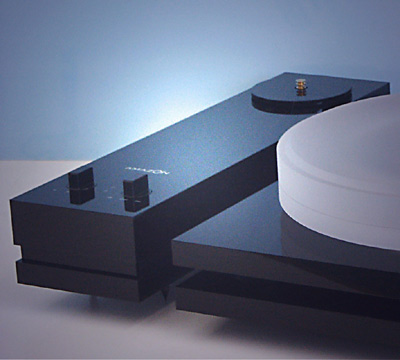

AMAZON 1 Superior TT with upgraded motor kit

Listed · 952 Views

1 Watcher

Items from this seller

This listing has ended.

Listings Similar to AMAZON

Time Left: Listing Sold

This listing has ended.

| Condition | |

| Payment methods | |

Contact seller after sale to pay viaVISA/Mastercard, Certified check, Personal check or Wire Transfer | |

| Ships from | El Cajon, CA, 92020 |

| Ships to | United States |

| Package dimensions | unspecified |

| Shipping carrier | unspecified |

| Shipping cost | |

| Research Pricing |

A Amazon Model 1 Turntable in fantastic condition. The Drive has been upgraded with a Maxon 110189 Motor fitted with an Origin Live Pulley and belt for superior speed stability. The power supply is a IC controlled 4.5 Ampere Regulator with 3 Transistor (LM317T) output. The table does 33.333 and 45.000 with uncanny speed stability for a belt drive. The upgraded drive system is vastly superior to the primitive battery operated / tiny motor / string driven this originally was supplied with.

Heres a link to the superior Maxon motor installed on this table

https://www.maxonmotor.co.uk/maxon/view/product/motor/dcmotor/amax/amax26/110189

There is no tonearm included in the price but we will be happy to supply any tonearm desired - the new Jelco TK950L would be a fantastic addition to this table this will add about $1700 to the price as we would have to make a custom arm board for it.

Heres a link to the TK950L we would recommend for this table

https://www.jelco-ichikawa.co.jp/cn3/tk-950l.html

Below from Amazons website

AMAZON 1

Chassis: The chassis of the drive is made from a special ICI material to ensure virtually no resonance. This is about a casted material, which has extremely good internal damping features, because of the added extras. We also use 6 LRP elements (Low Resilience Polymer) in our sub-chassis-construction, which decouples the plant level from the base on the one hand, and fights oscillation in the material on the other hand. The LRP elements are arranged in the chassis corners and around the platter bearing. When you compare these to metal spring constructions, there are no longer obnoxious material resonances of the spring or phenomenon’s of sway. The setting up is uncomplicated and quick, because you only have to care about the horizontal adjustment; no additional adjustment necessary, like for example spring elements etc.

Platter: The platter weights 5kg and is made from casted metacrylat. Its characteristics are very similar to the vinyl. During a very complex, temperature optimized process the platter gets drilled to its exact dimensions and afterwards follows the quenching and tempering of the surface. This process prevents stress in the material, which would affect the acoustic qualities. By using the plane platter profile we reach a big matching between vinyl and platter. Furthermore, resonance diffuser in the inner area of the platter eliminates the well-known material resonances in massive plastics platter in the area between 9 kHz and 13 kHz.

Bearing: The rotation-center of the platter is a ceramic ball in the middle of the inversed bearing. Both, bearing bush and vertical axis are made from multiple hardened steel. Accurate selection and very little tolerance guarantee a perfect, noiseless operation and long lifetime. All moving parts are supplied with a very thin but very good greasing special oil from a oil reservoir at the bearing base. Due to the massive body and the special geometry of the bearing, our platter bearing doesn’t tend to oscillate like most of the other. That is proven by objective measurements we made with the pulse measuring process. Pulses at different areas on the platter are dying out consistent and without excessiveness. An important advantage of inverted bearings is their high fulcrum, which minimizes tilting and commuting.

The heart of the drive is a DC-motor, which is usually used in nautical navigation devices. This motor is stored isolated and swimming in a massive box. The result is a absolute constant speed with perfect running smoothness.Power supply: The integrated rechargeable battery power supply is unique for analogue drives. In play mode, the rechargeable batteries as well as the motor are totally separated from the mains supply. Thereby, all the disturbing influences from the mains supply are kept away and a absolutely smooth running motor is guaranteed. All AMAZON motor units have a intelligent circuit, which monitors all parameters of the NiMH-batteries while charging and discharging. The system recharges the batteries automatically, when it is not in use. One charging cycle is enough to listen to 180 LP’s.

Dimensions (drive) (WxDxH):470 x 450 x 150 mm

Dimensions (motor unit)

(WxDxH):

fine adjustableBearing:Inverted Steel / ceramic-bearingDrive:DC-Motor with AMAZON LSC Speed ControlPower supply:NiMH batteries with automatic charging unitTonearms:Compatible with all tonearms till 12" and tangential tonearms.

No questions have been asked about this item.

Ask the seller a public question

You must log in to ask a question.

Return Policy

Return Window

Returns are not accepted on this item.